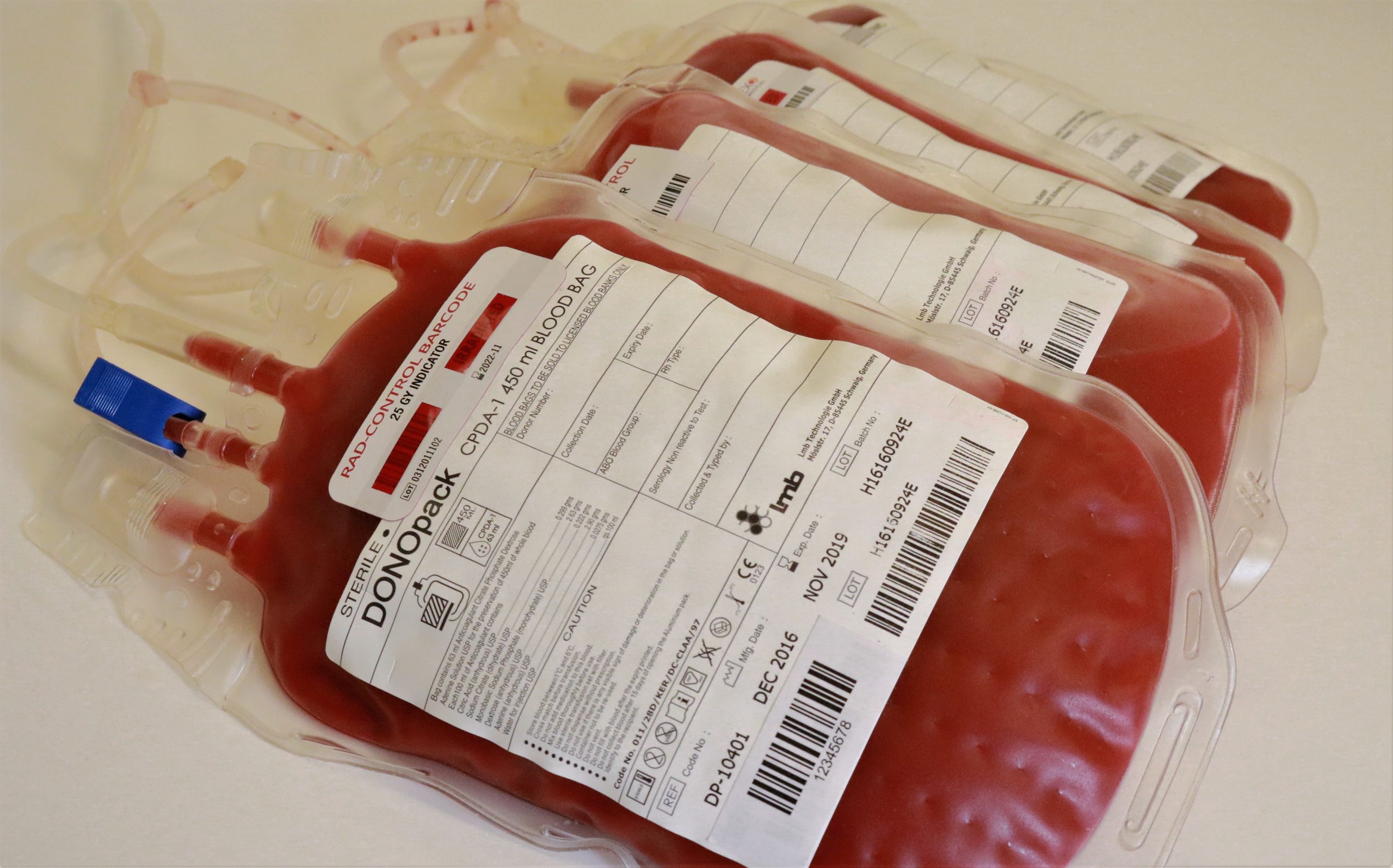

Your customers are

our customers

Our common interest is to offer new solutions and to streamline the workflow in blood banks and transfusion medicine. That’s why we support you in developing extensive knowledge of the market and our products. In addition to our personal updates, we provide you with useful background information and download options.

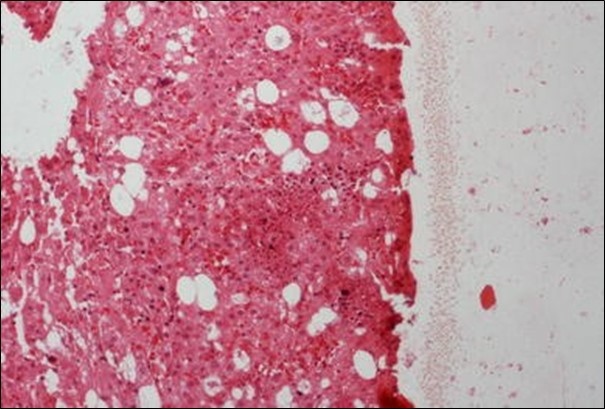

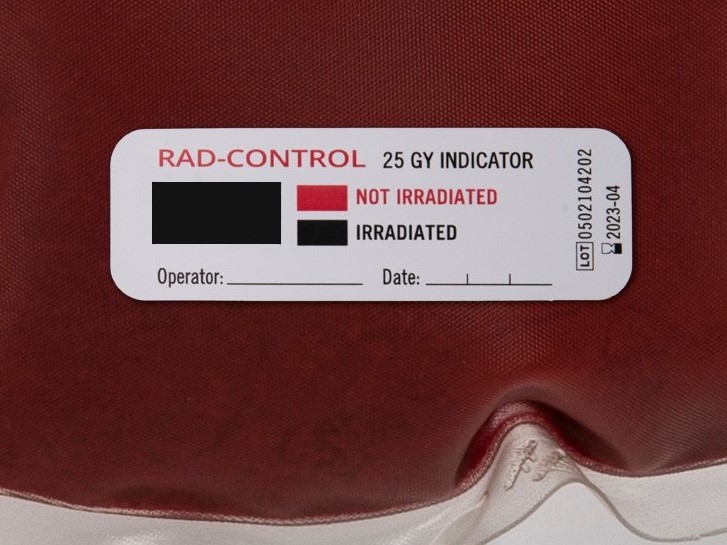

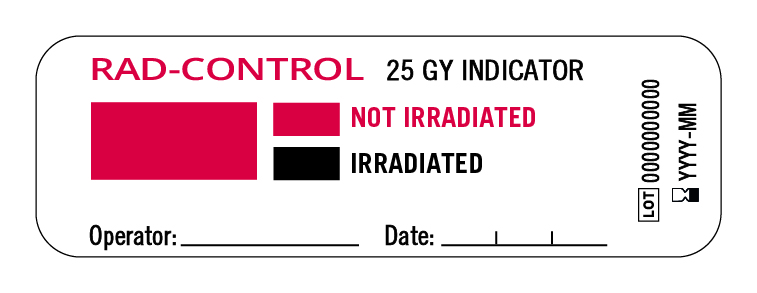

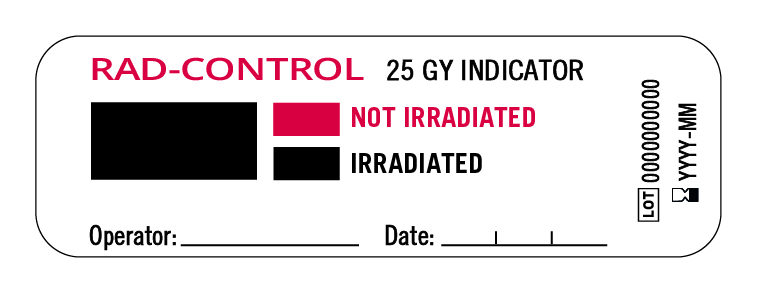

![What is blood irradiation [:de]Blutbesstrahlung vor einer Transfusion verhindert TA-GvHD[:en]Blood irradiation prior to transfusion prevents TA-GvHD[:]](https://onpointmedicals.at/wp-content/uploads/2021/11/What-is-blood-irradiation-scaled.jpg)