Blood centres and hospitals are subject to significant regulatory scrutiny to ensure quality in their operations. They have to observe a vast number of procedures, many documented on paper, whilst having to increase efficiency and maintain quality at the highest level.

Blood transfusion traceability is vital in this and includes the ability to trace each individual unit of blood or each blood component derived from this from the donor to its recipient. When patients are immunocompromised, for example, blood components have to be irradiated before they are transfused to avoid the severe and almost always fatal Transfusion-Associated Graft-versus-Host Disease (TA-GvHD). It is essential that these irradiation results are included in the blood unit documentation.

“The use of barcode indicators

is a logical next step.”

„

Traditional verification

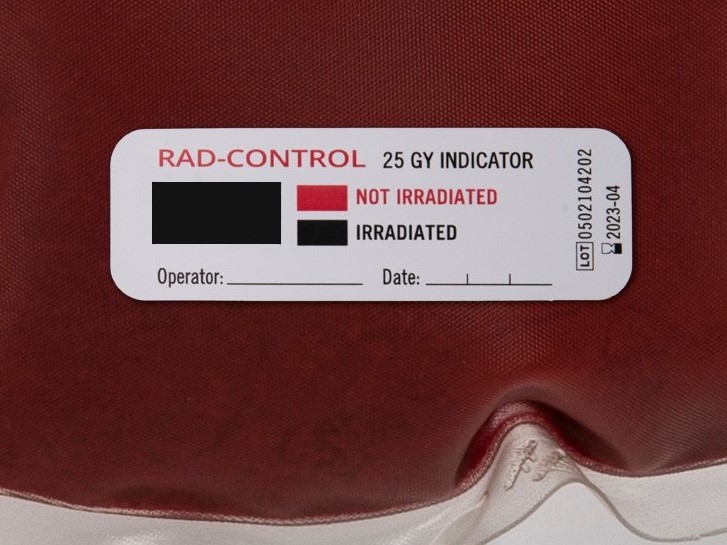

To confirm blood irradiation, indicators are affixed to blood bags before irradiation and they change colour when they are irradiated. User and date of irradiation are often written on those indicators and the results are documented in handwritten protocol lists. Positive irradiation results are transcribed from those lists and entered manually into the blood bank’s software much later in the process.

More stringent safety standards needed

But manual data entry is not always safe. International Blood Bank societies have issued new guidelines endorsing the use of electronic medical records for transfusions. In order to minimise input errors in the irradiated blood product information, the International Society of Blood Transfusion (ISBT) recommends in its Science Series published in 2020 that “The label on a blood component ready for use should contain information (preferably in eye and machine-readable codes) needed for safe transfusion, including additional information such as …. that indicating blood irradiation.”1 In its guideline released in 2021, the Australian and New Zealand Society of Blood Transfusion (ANZSBT) states that “wherever possible, automated data entry such as the use of barcodes or RFID, should be used to prevent manual data entry errors.“2

Digital verification

A new generation of barcode indicator labels, the Rad-Control Barcode, follows through with these recommendations and requirements. During irradiation, the indicator field turns into an electronically readable barcode. A second field then displays the word “irradiated” as visual proof. The barcode can be scanned directly from the blood product into the database, confirming the IT request for positively performed irradiation.

The barcode, as an electronically readable irradiation result, replaces and optimises a multitude of steps before a blood product can be released.

- Risk minimisation: handwriting and manual entering of the irradiation results is no longer needed

- Time saving: the digital irradiation results are immediately available

- Traceability: the irradiation results for each blood product are digitally documented and traceable

In order to comply with new standards and guidelines—to streamline the processes and simultaneously reduce input errors and costs—the use of barcode indicators is a logical next step. Leading blood banks such as the German Red Cross and the Belgian Red Cross have already adapted their IT systems accordingly.

Sources:

1 © 2020 The Author. Journal Compilation © 2020 Blackwell Publishing Ltd. ISBT Science Series (2020) 15, 207–231 Blood processing and components

2 © 2021 Australian and New Zealand Society of Blood Transfusion Ltd; Guidelines for the Implementation and use of Electronic Medical Records for Transfusion, ISBN No: 978-0-9803618-9-6

![[:de]Blutbesstrahlung vor einer Transfusion verhindert TA-GvHD[:en]Blood irradiation prior to transfusion prevents TA-GvHD[:]](https://onpointmedicals.at/wp-content/uploads/2021/11/What-is-blood-irradiation-scaled.jpg)