Blood Irradiation Indicators

Verifying

the irradiation

of blood products

RAD-CONTROL® labels are carefully engineered tools to verify blood irradiation. They support documentation and verification of irradiation exposure within the irradiation process, help to enhance efficiency and streamline protocols in blood banks and the transfusion medicine.

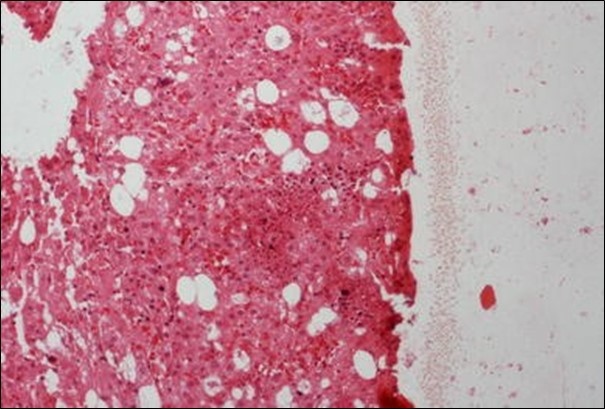

Why blood irradiation?

Our blog articles provide general background information on irradiation practices and topics from the field of blood management and transfusion practice that may be of general interest.

RAD-CONTROL® blood irradiation indicators are process indicators.

They only indicate exposure to irradiation and do not measure dose, confirm irradiation effectiveness, or determine clinical suitability of blood products.

Discover the solution that best suits your facility’s needs with three options to choose from. All three types are equipped with innovative technology and customisable features and can be stored at room temperature. All can also be used with equal efficacy for both Gamma and X-ray irradiation systems; however, they must never be used as a dosimeter.

irradiation results

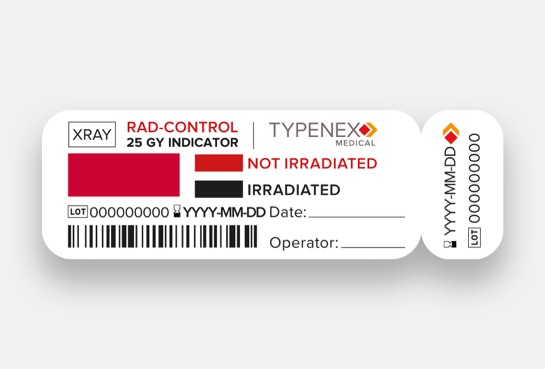

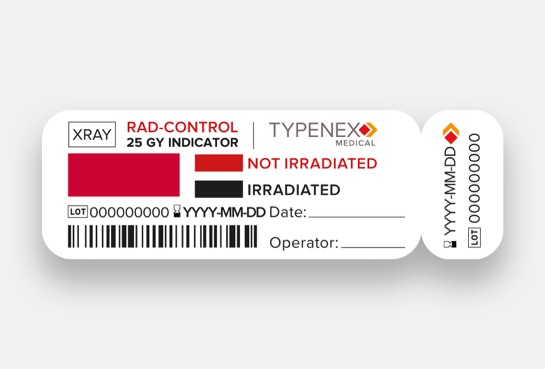

RAD-CONTROL® BARCODE

Automate your irradiation process with a new generation of blood irradiation indicators: the RAD-CONTROL® BARCODE is a sophisticated verification tool for the irradiation process of blood. Following ISBT’s recommendation for machine readable codes, the labels deliver electronic capabilities and scannable irradiation results for an automated, streamlined process.

Automate your irradiation process with a new generation of blood irradiation indicators: the RAD-CONTROL® BARCODE is a sophisticated verification tool for the irradiation process of blood. Following ISBT’s recommendation for machine readable codes, the labels deliver electronic capabilities and scannable irradiation results for an automated, streamlined process.

How it Works

With two indicator fields, the RAD-CONTROL® BARCODE is simply affixed to the blood product before irradiation. Innovative technology means that during the irradiation process the first indicator field turns into a barcode, and the second displays visual confirmation of irradiation. Once the blood has been irradiated, the verification result appears as a barcode. The result also appears in print in a second field. The barcode can be scanned to digitally verify that each individual blood bag was inside the irradiator and exposed to irradiation.

STEP 1 – IDENTIFY

STEP 2 – VERIFY

To utilise the RAD-CONTROL® BARCODE label and to confirm the irradiation exposure for process documentation purposes in your facility’s software, follow these steps:

STEP 1: Identify the blood product by scanning the blood product information.

STEP 2: Verify the blood irradiation process by scanning the electronically readable irradiation result.

The result is automatically stored in your database to allow for a more efficient and streamlined workflow.

The Benefits

| Simpler: No more protocol lists | the irradiation result is entered automatically into the Lab-IT system | |

| Easier: no manual notes on each indicator necessary | date and user are recorded automatically | |

| Faster: digital irradiation result immediately available | the entire documentation process is less time consuming | |

| Transparent | no manual data entry of irradiation results | |

| visual and digitally traceable documentation of irradiation

exposure within the workflow, supporting standardized process documentation |

||

| complete tracking of who did what and when with which product |

|

the irradiation result is entered automatically into the Lab-IT system | ||

| Easier: no manual notes on each indicator necessary | date and user are recorded automatically | ||

| Faster: digital irradiation result immediately available | the entire documentation process is less time consuming | ||

| Transparent | no manual data entry of irradiation results | ||

| visual and digitally traceable documentation of irradiation

exposure within the workflow, supporting standardized process documentation |

|||

| complete tracking of who did what and when with which product |

Easy implementation

Setting up your digital irradiation verification is simple and easy — irradiators and the application of the irradiation labels remain unchanged.

All you need is:

- A barcode scanner

- One additional data field in your existing software: this data field simply needs to ask for the performed irradiation. The barcode then confirms the request by reading “OK”.

- The RAD-CONTROL® BARCODE indicator

RAD-CONTROL®

Product Features

| Shelf life Barcode Shelf life Standard Shelf Life Scale |

16 months 24 months 24 months |

|

| Excellent adhesion strength | firm label hold | |

| Storage at room temperature | no refrigeration required | |

| Customisation | free choice of size, design and other features | |

| ISBT 128 bar-coded lot numbers | on request | |

| Quality standard | ISO 13485 | |

| X-ray or Gamma sources | indicators work equally with both systems |

| Haltbarkeit | 24 Monate | |

| Exzellenter Kleber | starke Klebekraft | |

| Aufbewahrung bei Zimmertemperatur | keine Tiefkühlung notwendig | |

| Individuelle Anpassungen möglich | Größe, Design, Sprache frei wählbars | |

| ISBT 128 Barcode Chargennummern | auf Anfrage | |

| Qualitätsstandard | nach ISO 13485 geprüft | |

| X-ray oder Gamma Bestrahlung | Indikatoren funktionieren gleichwertig mit beiden Bestrahlungsquellen |

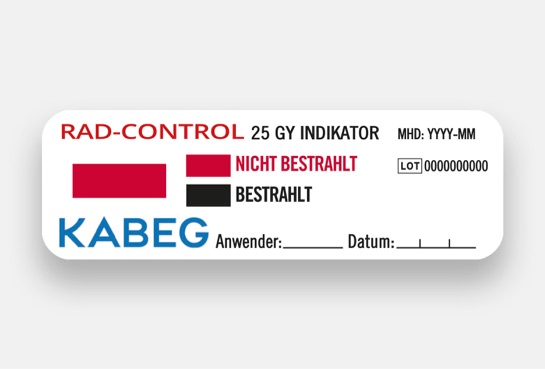

Customisation

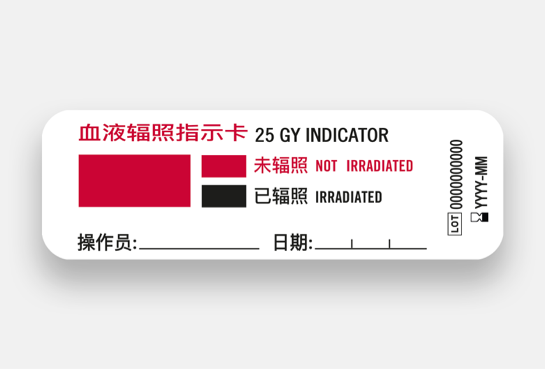

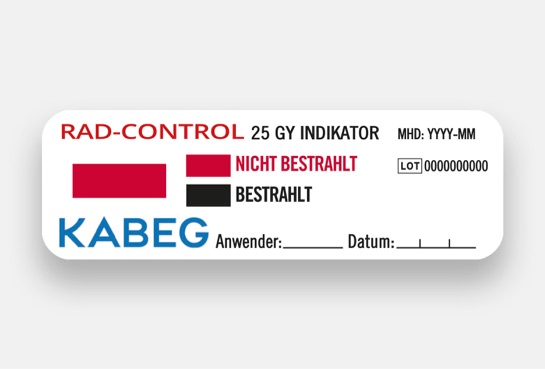

Language

To minimise risks of misinterpretation, the medical staff needs to understand what they are reading. We are happy to provide labels in any preferred language.

Communication

You want to place additional information or the logo of your blood centre on the labels? Not a problem—we customise your indicators accordingly.

Add-ons

There is virtually no limit to your requests: peel-off sections, ISBT 128 barcodes for lot numbers and many more features. Just let us know your requirements—we deliver.

Customisation

Language

To minimise risks of misinterpretation, the medical staff needs to understand what they are reading. We are happy to provide labels in any preferred language.

Communication

You want to place additional information or the logo of your blood centre on the labels? Not a problem—we customise your indicators accordingly.

Add-ons

There is virtually no limit to your requests: peel-off sections, ISBT 128 barcodes for lot numbers and many more features. Just let us know your requirements—we deliver.

Blood banks working with

RAD-CONTROL® BARCODE

The Belgian Red Cross Flanders has chosen us as a supplier of unique and customised indicators which facilitate the digital verification of blood irradiation. We would like to thank Innolabel and the Red Cross Flanders for realising this innovative customer project.

The German Red Cross Frankfurt was our first validation partner for RAD-CONTROL® BARCODE indicators. The results of an extensive head-to-head comparison with previously used indicators was published at the DGTI conference in 2017.

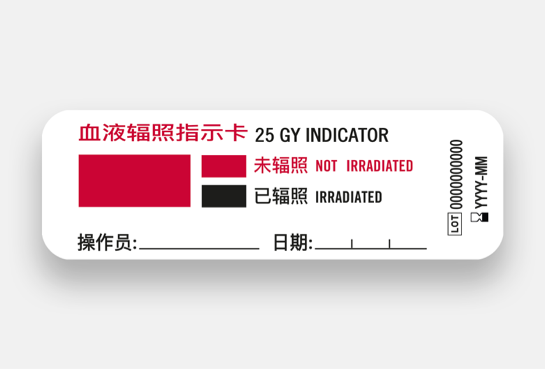

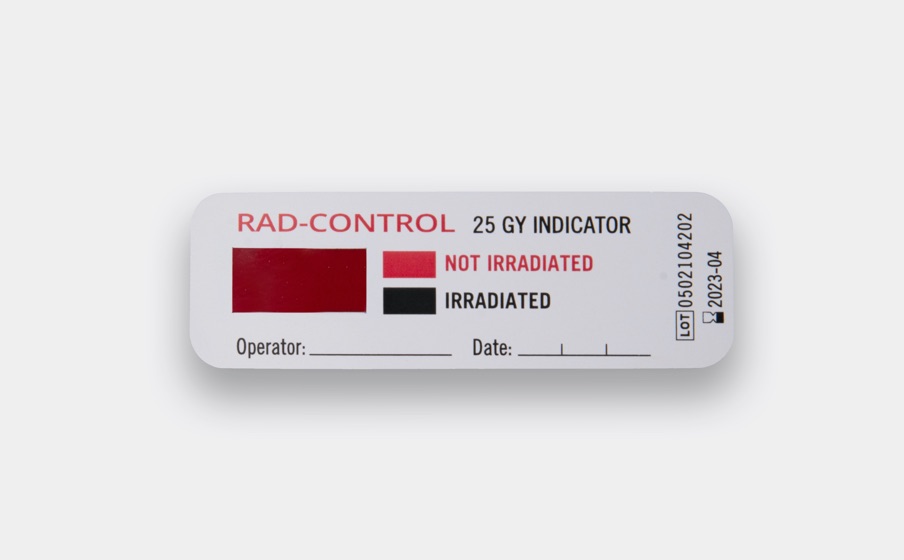

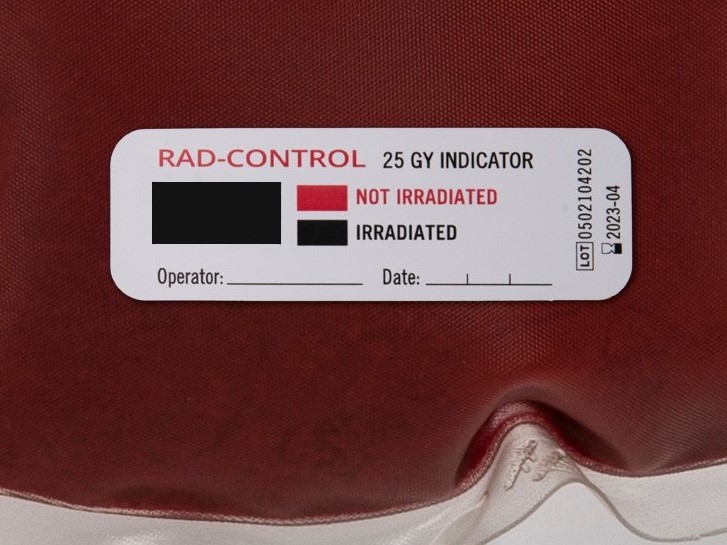

RAD-CONTROL® STANDARD

The Standard version of the RAD-CONTROL® product line features a simple, high-quality design that sets the industry standard. It works with the discolouration of red to black. This results in YES/NO information on whether the irradiation was performed. The colour change is reliable and self-explanatory providing clear information as “not irradiated/irradiated”. An operator and date field allow for further written documentation on the labels. A whole range of customisations – from lot code barcodes to peel-off labels are optional features.

A simple and logical solution widely used in blood banks and medical centres worldwide.

The Standard version of the RAD-CONTROL® product line features a simple, high-quality design that sets the industry standard. It works with the discolouration of red to black. This results in YES/NO information on whether the irradiation was performed. The colour change is reliable and self-explanatory providing clear information as “not irradiated/irradiated”. An operator and date field allow for further written documentation on the labels. A whole range of customisations – from lot code barcodes to peel-off labels are optional features.

A simple and logical solution widely used in blood banks and medical centres worldwide.

NOT IRRADIATED

IRRADIATED

RAD-CONTROL® STANDARD

How it works

With only one red indicator field, the RAD-CONTROL® STANDARD is simply affixed to the blood product before irradiation. When exposed to irradiation, the colour of the indicator field changes from red to black. After irradiation, the black field indicates “irradiated” and is a reliable and self-explanatory proof that each individual blood bag was inside the irradiator and exposed to irradiation.

Features & Benefits

All RAD-CONTROL® indicators are carefully produced and comprehensively tested in accordance with our ISO 13485 quality management system in order to support consistent and standardized irradiation process documentation. They can be fully customised by size, language and any other additional information. Check out the full scope of features and benefits.

blood irradiation indicator

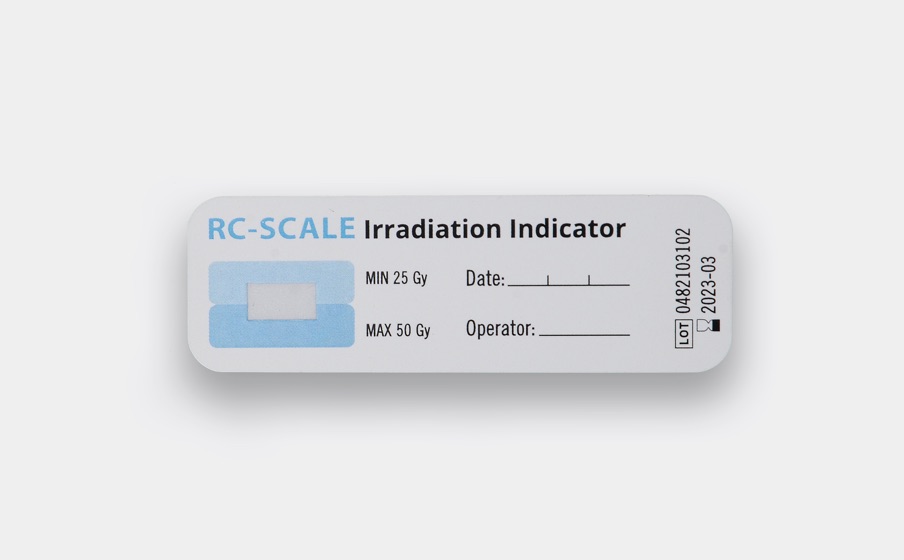

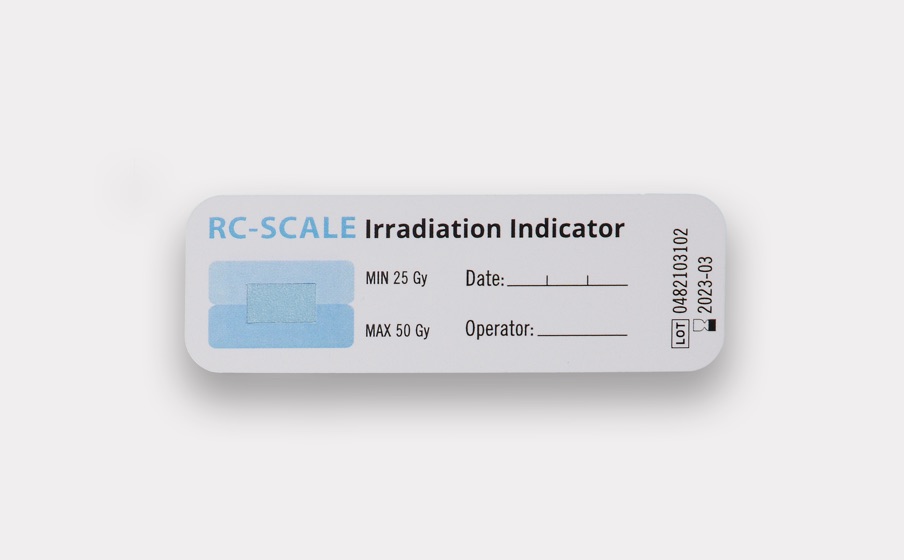

RAD-CONTROL® SCALE

The semi-quantitative version of the RAD-CONTROL® product line is an alternative option for verifying blood irradiation. This indicator label provides visual confirmation and classifies irradiation results between a minimum and a maximum value. Lot code barcodes or other add-ons are optional customisation features.

The semi-quantitative version of the RAD-CONTROL® product line is an alternative option for verifying blood irradiation. This indicator label provides visual confirmation and classifies irradiation results between a minimum and a maximum value. Lot code barcodes or other add-ons are optional customisation features.

NOT IRRADIATED

IRRADIATED

RAD-CONTROL® SCALE

How it works

Before irradiation, the RAD-CONTROL® SCALE is simply affixed to the blood product and the indicator field shows a pale pink. When exposed to irradiation, the indicator field changes from pale pink to blue. Unique colour-changing material produces different shades of blue related to the amount of radiation applied.

Features & Benefits

All RAD-CONTROL® indicators are carefully produced and comprehensively tested in accordance with our ISO 13485 quality management system in order to avoid risks in your process. They can be fully customised by size, language and any other additional information. Check out the full scope of features and benefits here.

Questions?

Simply contact us.

![[:de]Blutbesstrahlung vor einer Transfusion verhindert TA-GvHD[:en]Blood irradiation prior to transfusion prevents TA-GvHD[:]](https://onpointmedicals.at/wp-content/uploads/2021/11/What-is-blood-irradiation-scaled.jpg)